Forklifts and Carbon Monoxide

This fact sheet is for ‘persons conducting a business or undertaking’ (PCBUs) that use forklifts. It explains the risks of carbon monoxide poisoning when using fuel powered forklifts and how to keep your workers healthy and safe.

Download:

Forklifts and carbon monoxide poisoning (pdf 693 KB)

Forklifts powered by liquefied petroleum gas (LPG), petrol and diesel produce potentially deadly carbon monoxide gas. Carbon monoxide can quickly build up when using forklifts indoors without enough ventilation. Carbon monoxide is a poisonous gas that has no smell or taste. This means you can inhale it without realising. Breathing it in can make workers unwell, and it can kill. It is impossible to detect without proper equipment.

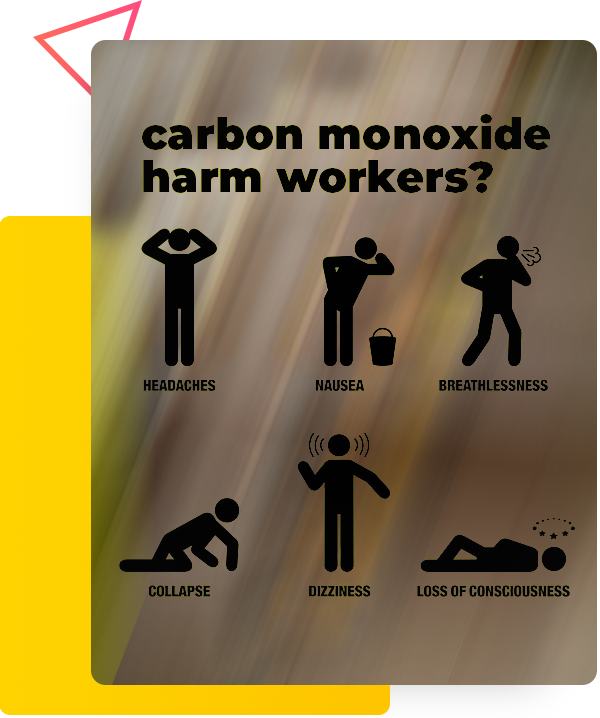

How can carbon monoxide harm workers?

Workers can be overcome by carbon monoxide without even realising they have been exposed to it. A headache is the most common symptom of mild carbon monoxide poisoning.

Other symptoms include:

- buildings with poor ventilation ie no mechanical ventilation to extract harmful gases to the outside

- dizziness

- nausea (feeling sick) and vomiting

- tiredness and confusion

- stomach pain

- shortness of breath and difficulty breathing.

Prolonged exposure to carbon monoxide gas can also damage an unborn child.

Figure 1: Avoid using LPG and other fuel-powered forklifts in coolstores and areas with poor ventilation

Figure 2: Use electric forklifts in coolstores and areas with poor ventilation

How to keep workers safe

PCBUs have a duty to eliminate risks to health and safety, so far as is reasonably practicable. Therefore eliminating the source of carbon monoxide from the workplace by using electric powered forklifts instead of fuel-powered forklifts should be the first option you consider.

Use carts, trolleys, palletizers or similar equipment in rooms or buildings that are small, or have poor ventilation.

If you have to use a fuel-powered forklift:

- Develop a policy on the use of forklifts and management of the risks

- Install carbon monoxide alarms on forklifts or in buildings, and have the alarms regularly calibrated

- Restrict forklift use in poorly ventilated or confined areas. Turn them off when not in use

- Tune regularly, and test for carbon monoxide emissions. An out-of-tune forklift will overload the catalytic converter. Keeping diesel forklifts well-maintained will also reduce the diesel exhaust emissions which can cause cancer

- Ensure workers know how to report any problems or notifiable exhaust fumes

- Inform workers of the risk of carbon monoxide poisoning

Monitoring the work environment

PCBUs have a duty to monitor the health of workers and the conditions at the workplace to ensure that workers are not injured or made ill by their work. When work activities may expose workers to carbon monoxide WorkSafe recommends that the PCBU considers carrying out exposure monitoring to determine the concentration of carbon monoxide in the workplace. Exposure monitoring should be carried out by occupational hygienists or other suitably trained personnel. They will compare the levels of carbon monoxide present in your workplace with the workplace exposures standard (WES) and can advise you whether you need to do more to manage the risk.

Exposure monitoring should be undertaken regularly to check the effectiveness of controls. If the controls are not working seek advice on improving controls from an occupational health specialist.

Workplace Exposure Standards

Exposure to carbon monoxide should be controlled and the following WES should not be exceeded.

| Exposure period | WES | Measurement |

|---|---|---|

| 8 hours | 25ppm | Average exposure over 8 hours |

| 1 hour | 50ppm | Average exposure over 1 hour |

| 30 minutes | 100ppm | Average exposure over 30 minutes |

| 15 minutes | 200ppm | Average exposure over 15 minutes |

| Ceiling (instant) | 400ppm | Celing (instant) reading |

The WES are intended to be used as guidelines for people qualified in occupational health practice. Further information on the interpretation of this WES should be sought from the Workplace Exposure Standard and Biological Exposure Indices 2016.

Monitoring worker health

There is no routine health monitoring for carbon monoxide exposure but a medical examination is recommended to identify those workers who may be more susceptible to carbon monoxide poisoning ie history of coronary heart disease, anaemia, pregnancy.

The PCBU should follow the recommendations of an occupational health practitioner with experience in health monitoring when determining what type of health monitoring or examination is required.

Anyone who has been affected by carbon monoxide poisoning, even if they only have a headache, must see a doctor or go to the nearest hospital as soon as possible. A blood test should be carried to determine if carbon monoxide poisoning has occurred. WorkSafe should be notified in cases where a person has been admitted to hospital for treatment.

What to do in an emergency

If someone at work seems to be affected by carbon monoxide poisoning, it’s important to ACT QUICKLY:

- Turn off the forklift to stop more carbon monoxide entering the workplace, and make sure that someone else knows you are entering the area

- If it’s impractical to turn off the forklift, ensure breathing apparatus is worn by rescuers

- Open any doors and increase air flow if possible

- Get the affected person outside into fresh air – if the person is unconscious, call 111

- If there’s no heartbeat, begin CPR

Peace of mind with dependable fuel supply, when you need it

Our Business is Customer Satisfaction.